◆ Product Center

-

SHJ-A,B SERIES TWIN SCREW EXTRUDER

-

SHJ-C SERIES TWIN SCREW EXTRUDER

-

SHJ-D SERIES TWIN SCREW EXTRUDER

-

SJ SERIES SINGLE SCREW EXTRUDER

-

KP SERIES TWO STAGE EXTRUDER

-

KDS SERIES KNEADER PRODUCTION LINE

-

SJZ CONICAL TWIN SCREW EXTRUDER

-

LOOS-IN-WEIGHT FEEDING SYSTEM

-

PEIIETIZING SYETEM

-

AUXILIARY EQUIPMENT

-

TYPICAL APPLICATION IN CUSTOMER'S SITE

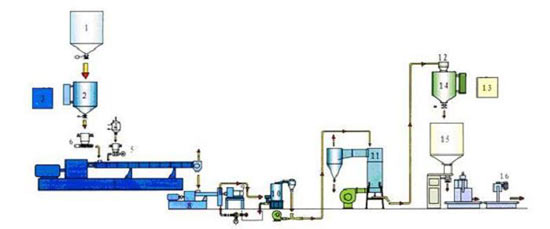

Silicane Cross-linking Cable Material, Pipe Material Pelletizing Production Line

(Summary description)Characteristic: Large draw-ratio co-rotating twin-screw extruder finishes the plastic mixing and reaction grafting in steps; low-speed single-screw extruder can realize low-temperature pressure reduction, extrusion and pelletizing.Compared with a single-step unit, it has larger operating flexibility, more optimal technological condition and relevantly ideal product performance.

1. Raw Material Bin; 2. Drying Hopper; 3. Molecular Sieve Dryer; 4. Raw Material Tank;

5. Weightlessness Metering Pump; 6. Weightlessness Electronic Scale; 7. Twin-screw Extruder;

8. Single-screw Extruder; 9. Water-ring Pelletizer; 10. Centrifugal Dehydrator; 11.Fludized Bed

12. Vacuum Charging Machine; 13. Molecular Sieve Dryer; 14. Drying Hopper;

15. Finished Product Storage Bin; 16. Vacuum Packing Machine

Characteristic: Large draw-ratio co-rotating twin-screw extruder finishes the plastic mixing and reaction grafting in steps; low-speed single-screw extruder can realize low-temperature pressure reduction, extrusion and pelletizing.Compared with a single-step unit, it has larger operating flexibility, more optimal technological condition and relevantly ideal product performance.

Contact Us

Landline:0086-25-84757296 、 0086-25-52111918

Tel:13813918398 、 13813086079 、 13390929258 、 13390757638

E-mail: info@hgextruder.com 、 pan@hgextruder.com 、

Add:NO.2-6 Wangshan Road. Taohong Industrial Park. Taowu Hengxi. Jiangning District, Nanjing, China

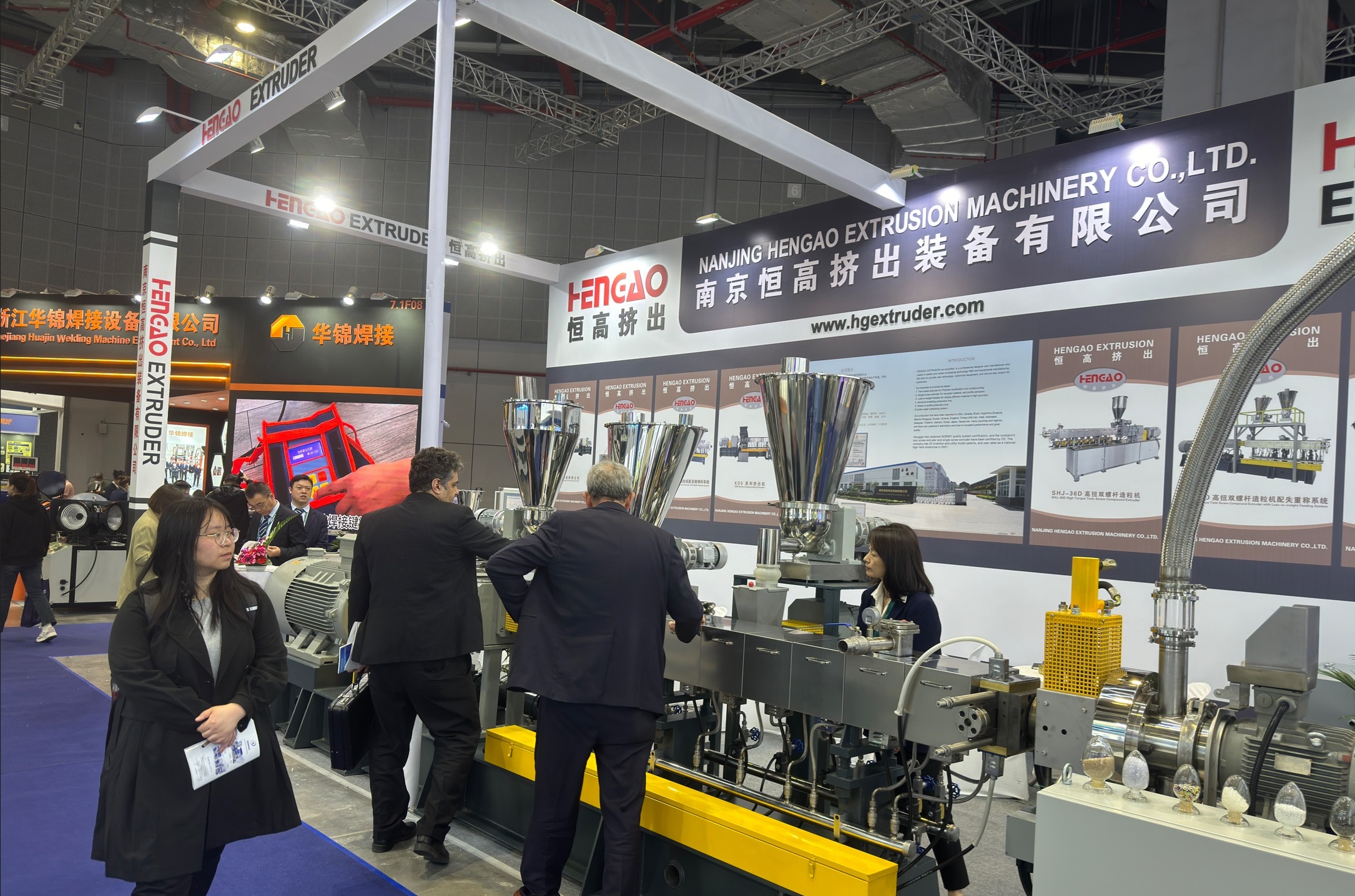

NANJING HENGAO EXTRUSION MACHINERY CO.,LTD. 苏ICP备15056870号-1