◆ Product Center

-

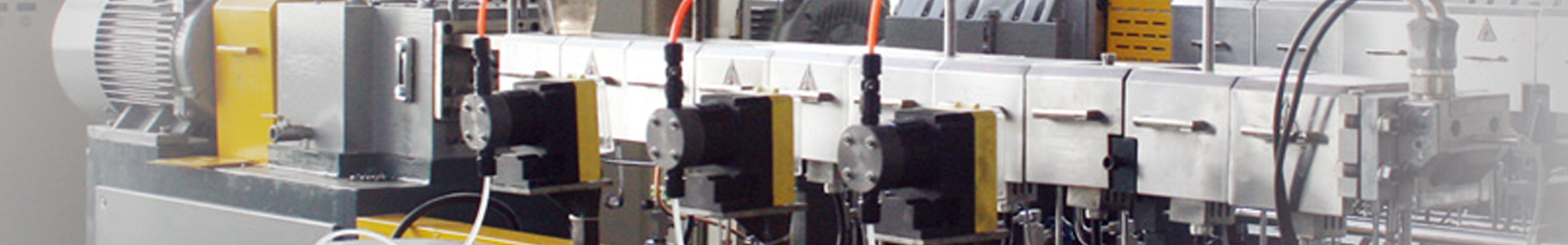

SHJ-A,B SERIES TWIN SCREW EXTRUDER

-

SHJ-C SERIES TWIN SCREW EXTRUDER

-

SHJ-D SERIES TWIN SCREW EXTRUDER

-

SJ SERIES SINGLE SCREW EXTRUDER

-

KP SERIES TWO STAGE EXTRUDER

-

KDS SERIES KNEADER PRODUCTION LINE

-

SJZ CONICAL TWIN SCREW EXTRUDER

-

LOOS-IN-WEIGHT FEEDING SYSTEM

-

PEIIETIZING SYETEM

-

AUXILIARY EQUIPMENT

-

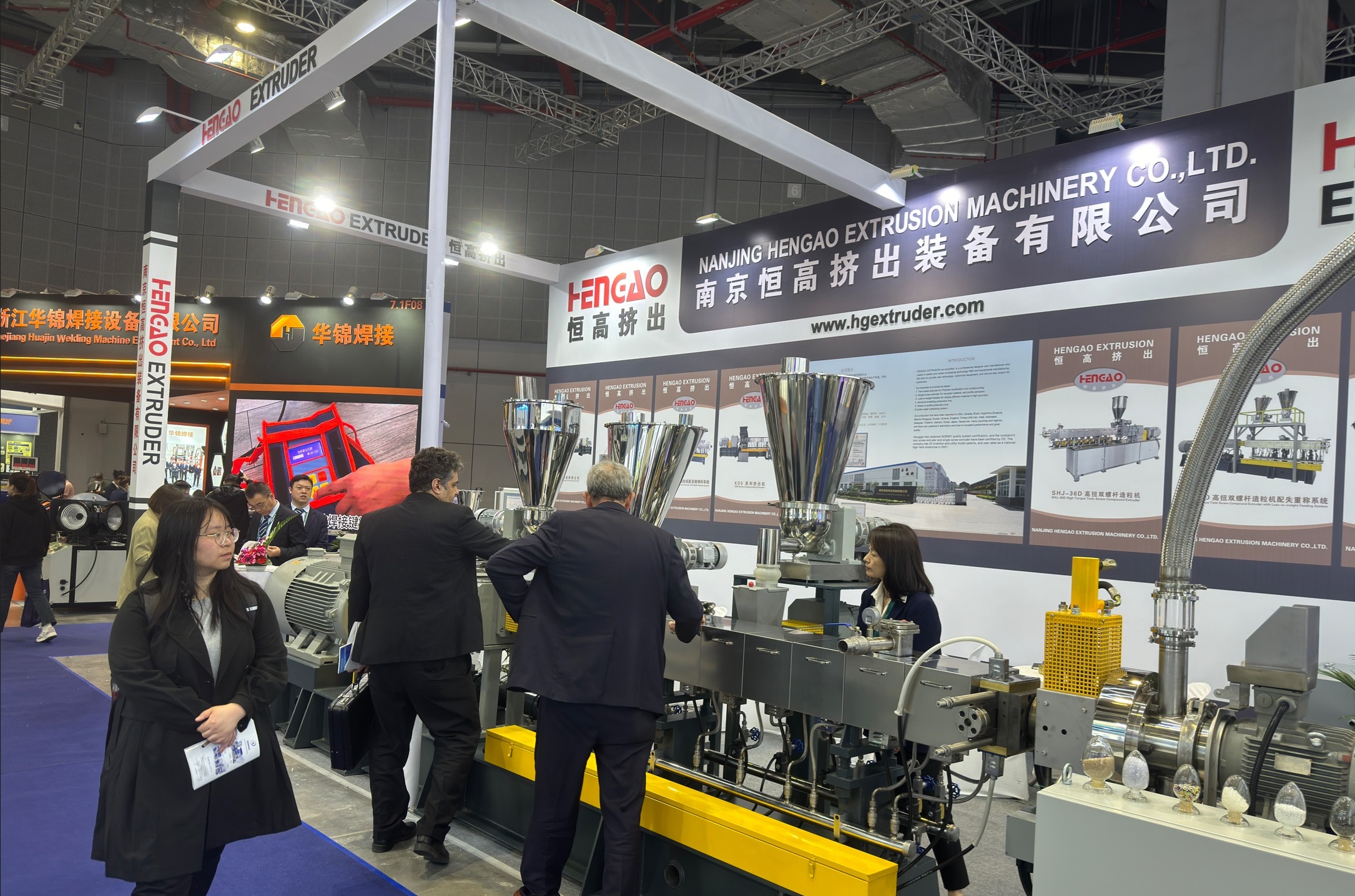

TYPICAL APPLICATION IN CUSTOMER'S SITE

Twin-screw Pelletizing Unit after Evaporation and Impurity Removal

(Summary description)Application: High-capacity impurity removal and exhaust, polymers or monomers, low polymer or solvent removal, condensation and stabilization for high molecular materials such as CPE, CPP, CSPE, SBSK resin, EVA, PMMA, ABS, POM, PS, PC, and butadiene rubber.

1.Reaction Vessel; 2. Melt Metering Pump; 3. Exhaust Plant; 4. First-step Twin-screw Extruder; 5. Second-step Twin-screw Extruder; 6. Additive or Carrier Injection; 7. Water Channel; 8. Drying Machine; 9. Pelletizer; 10. Finished Product Storage Bin; 11. Weighing and Bagging

Application: High-capacity impurity removal and exhaust, polymers or monomers, low polymer or solvent removal, condensation and stabilization for high molecular materials such as CPE, CPP, CSPE, SBSK resin, EVA, PMMA, ABS, POM, PS, PC, and butadiene rubber.

Contact Us

Landline:0086-25-84757296 、 0086-25-52111918

Tel:13813918398 、 13813086079 、 13390929258 、 13390757638

E-mail: info@hgextruder.com 、 pan@hgextruder.com 、

Add:NO.2-6 Wangshan Road. Taohong Industrial Park. Taowu Hengxi. Jiangning District, Nanjing, China

NANJING HENGAO EXTRUSION MACHINERY CO.,LTD. 苏ICP备15056870号-1